Waste

Water Discharge Waste

Water Discharge

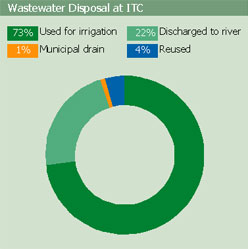

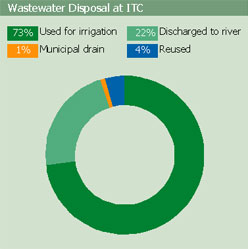

ITC endeavours to achieve zero effluent discharge in all its

Units. Reflecting the efforts and progress in this direction, a number of ITC Units –

the Cigarette Factories at Bengaluru and Saharanpur, the ITC Group Research &

Development Centre at Bengaluru, the Leaf Plant at Anaparti, the Packaging & Printing

factory at Tiruvottiyur, and the Cast Coating Plant at Bollarum, near Hyderabad, already

utilise the entire quantity of their treated effluents for operating their cooling towers,

flushing toilets, gardening and other appropriate activities.

| Treated

Wastewater Disposal in Paper Business |

|

2002–03 |

2003–04 |

| River |

26% |

23% |

| Irrigation |

74% |

77% |

ITC’s Paperboard and

Specialty Paper Units have made significant progress in the endeavour to ensure that the

entire volume of their treated effluents is used for agriculture. This is in line with the

recommendation of the Ministry of Environment & Forests, Government of India, and the

Central Pollution Control Board (CPCB), in the voluntary charter that they have proposed

for the 17 most polluting industries, including the paper industry. These Units already

implement stringent water conservation measures. But as the manufacture of paper and

paperboards is intrinsically water-intensive, these Units still discharge some treated

water.

The voluntary charter proposed by MoEF and

CPCB recommends that paper units move to 100% discharge of treated effluents for farming

and agriculture.

Chemical, oil and

fuel spills Chemical, oil and

fuel spills

ITC’s EHS guidelines require all the Units of the Company to plan the storage and

handling of chemicals, oils and fuels in properly designed and tested storage vessels. The

Company has effective spill control arrangements and infrastructure like bunds and

retaining walls in its Units. These are routinely checked to ensure that they are in good

condition. No spills of chemicals, oils, or fuels were noted in 2003–04 by any ITC

unit.

Incidents of

fines for non-compliance

ITC maintains a ‘beyond compliance’ status in EHS performance in its Units. Any

non-compliance is dealt with immediately. The Units promptly respond to any inadvertent

violation pointed by stakeholders or corporate EHS auditors. As a result, there were no

fines for non-compliance imposed during 03–04.

Total

environmental expenditure

ITC remains committed to a very high level of EHS performance. This is backed by suitable

investments and financial commitment. During 2003–04 ITC Units incurred a capital

expenditure of Rs. 2.6 million and a revenue expenditure of Rs. 11.65 million on EHS

projects. |

Waste

Water Discharge

Waste

Water Discharge Chemical, oil and

fuel spills

Chemical, oil and

fuel spills