Environmental Performance

Minimising Carbon Intensity and Adopting a Low Carbon Growth Path

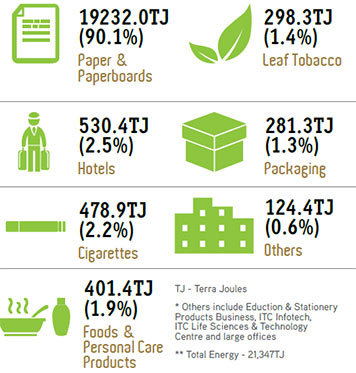

Energy Consumption Within ITC Across Businesses (2012-13)

Progress In Reduction of Specific Energy Consumption In ITC’s Businesses

Progress In Reduction of Specific Energy Consumption In ITC’s Businesses

A focused approach on energy conservation through rigorous third party audits and implementation of the recommendations and better capacity utilisation resulted in substantial reduction in specific energy consumption.

In the Paperboards and Specialty Papers Business, the four factories, Bhadrachalam, Tribeni, Bollaram and Kovai, together accounted for 90.1% of the total energy consumption in ITC. ITC’s Paperboards and Specialty Papers Business has been rated the most energy efficient in the Indian Paper and Paperboards sector, according to the Centre for Science and Environment, New Delhi, (Challenge of the New Balance, CSE, 2010).

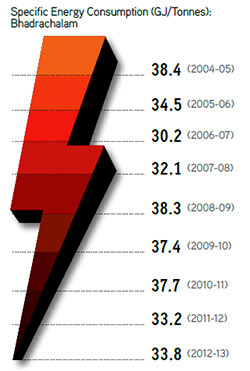

In 2012-13, the specific energy consumption (energy used per tonne of product) in the Unit at Bhadrachalam, which alone accounts for 76% of total energy consumption in ITC, has increased by 1.7% over the past year primarily due to the commissioning and stabilisation of a new Paper Machine. The Kovai Unit, which has increased the utilisation of electricity from its wind power plant, reduced the use of electricity generated from its coal, lignite & biomass based captive power plant and recorded a 18.4% reduction in primary energy consumption which together with energy conservation measures implemented 530.4TJ (2.5%) Hotels 401.4TJ (1.9%) Foods & Personal Care Products Specific Energy Consumption (GJ/Tonnes): Bhadrachalam 38.4 (2004-05) 34.5 (2005-06) 30.2 (2006-07) 32.1 (2007-08) 37.4 (2009-10) 37.7 (2010-11) 33.2 (2011-12) 33.8 (2012-13) 38.3 (2008-09) 66 ENVIRONMENTAL PERFORMANCE SUSTAINABILITY REPORT by the Unit resulted in a 21.0% reduction in specific energy consumption as compared to the previous year. The Tribeni Unit has also recorded a reduction of 33.2% in specific energy consumption which is primarily due to the change in methodology of computing primary energy consumption by using measured calorific values of coal consumed (different grades), instead of default calorific value from IPCC as adopted during the previous years, together with energy conservation measures implemented by the Unit.

There has been a substantial improvement in the specific energy consumption at the Soap and Shampoo Units of the Personal Care Products Business at Manpura (as illustrated below) which is primarily due to improvement in capacity utilisation and implementation of energy conservation measures by the Unit. Other Units, which performed well in improving specific energy consumption over the previous year, are:

Additional data on energy conservation measures implemented by ITC units are available at www.itcportal.com under Report and Accounts 2013.

ITC has registered several Clean Development Mechanism (CDM) projects with UNFCCC (United Nations Framework Convention on Climate Change) under the Kyoto Protocol.

In addition, ITC is well positioned to leverage other opportunities arising out of India-specific schemes such as Perform, Achieve and Trade (PAT) or Renewable Energy Certificates (RECs) promoted by the Government of India.