In India, water is a very precious resource with the country accounting for 18% of the

world’s population and only 4% of global fresh water resources. India’s vision

of achieving over 10% GDP growth and becoming the global manufacturing hub will strain its

already scarce water resources, making it incumbent upon individuals and corporations to

use this precious resource with utmost care and responsibility.

ITC’s sustainability objective

focuses on:

• Conservation, Audit and

Benchmarking – to achieve the lowest specific water consumption (water used per unit

of production)

• Zero water discharge –

treating and recycling all the waste water, thereby not only reducing fresh water intake

but also preventing pollution of fresh water resources

• Creating a positive footprint

– through rainwater harvesting, both at the Company’s premises and through

external watershed development projects.

ITC’s total fresh water intake of

25.58 million kilolitres (KL) during 2005-06 is slightly higher than the previous

year’s (24.98 million KL), despite a significant growth in all its businesses.

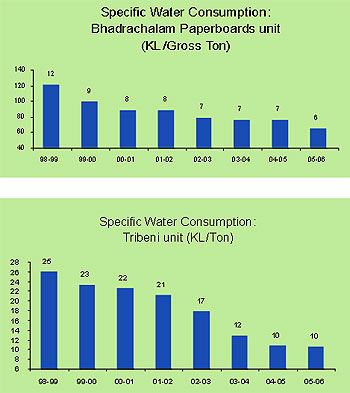

The three Paperboards and Specialty Paper

units at Bhadrachalam, Tribeni and Kovai together account for 91.9% of the total fresh

water intake by ITC. Implementing water audit recommendations, deploying advanced

technology, increasing awareness and improving resource management have enabled these

three units to reduce specific water consumption by 13%, 2% and 18%, respectively.

Similarly, ITC’s Cigarette factories

reduced fresh water intake by 6%, Leaf Processing Plants by 19%, Packaging & Printing

factories by 16% and Hotels by 2% – despite significant growth in volumes. |

Zero Water Discharge:

Closing the water loop in a factory or hotel not only results in minimum fresh water

usage, it also prevents pollution of the environment, including fresh water sources. The

Cigarette factories at Bengaluru & Saharanpur, Leaf Processing Plants at Anaparti

& Chirala, Packaging & Printing unit near Chennai, Research Centres at Bengaluru

& Rajahmundry, Paperboards unit at Bollarum, ITC Green Centre at Gurgaon, ITC Sonar

Bangla & WelcomHotel Rajputana Palace recycled all their treated effluents. The

recycled water was used mostly for flushing toilets, cooling towers and gardening.

|