| Global Warming refers to an average increase in

the earth’s temperature, which in turn causes adverse changes in climate. Climate

change may lead to changes in rainfall patterns, a rise in sea level, and a wide range of

impact on plants, wildlife and humans. Scientists are concerned about global warming

caused by human activities. Greenhouse gases trap energy in the atmosphere and thereby

make the earth warmer. Reduction of greenhouse gases discharged into the atmosphere is the

answer to the challenge of global warming. ITC’s strategy on energy sustainability

and its contribution in reducing global warming can be summarised as follows:

Ensuring

availability and sustainability of energy supply Ensuring

availability and sustainability of energy supply

Benchmarking

specific energy consumption to progressively achieve reduction Benchmarking

specific energy consumption to progressively achieve reduction

Using renewable

sources, including energy from wastes Using renewable

sources, including energy from wastes

Creating a

positive environmental footprint through sequestration Creating a

positive environmental footprint through sequestration

|

|

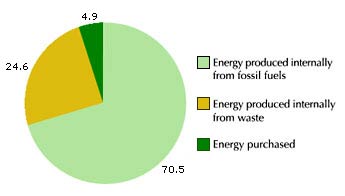

Energy Supply & Sustainability |

ITC operations consumed 12,085 Terra Joules of energy in 2004-05 (11,439 Terra Joules

in 03-04). 95.11% of this energy was generated internally. Almost a quarter (24.6%) of the

total energy was produced from wastes. Only 4.89% energy was purchased in the form of

electricity.

Energy Scenario in ITC (in percentage)

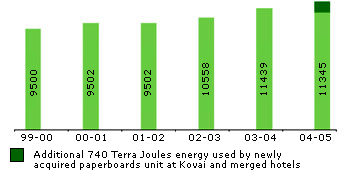

On a like to like basis, for the operating units reported in the

Sustainability Report 2004, actual consumption of energy has in fact gone down by 0.82%

from 03-04, in spite of a 9.4% growth in paper production, which is an energy-intensive

process.

Energy Consumption by ITC Units (Terra Joules)

|

|

|

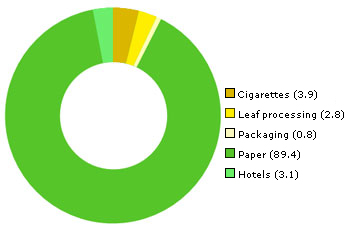

Benchmarked Specific Energy

Consumption |

The Bhadrachalam, Tribeni and Kovai units of the Paperboards and Specialty Papers

Division together account for over 89% of the total energy utilised by ITC operations.

Energy Consumption by ITC businesses (in percentage)

Significant efforts, therefore, continue to be directed towards minimising specific

energy consumption, a measure of energy requirement per unit of production, in these paper

and paperboards units.

Bhadrachalam

Energy consumption per tonne of paperboard in the Bhadrachalam unit decreased to 33.3

GJ (an improvement of 7.75% over the previous year). The specific energy consumption in

the last three years has been slightly higher than the lowest consumption figures achieved

in 00-01, due to the commissioning of two new paper machines and a substantially larger

pulp mill. |