EHS

Initiatives at the Newly Acquired Paperboards Unit - Kovai

Post acquisition of the Kovai paperboards unit on March 19, 2004, a massive

training programme for all employees, including service providers’ workmen, was

launched to raise quality, environment, occupational health and safety levels to ITC

standards. The unit invested 2,260 mandays in training managers, workmen and service

providers. Thanks to focused efforts at all levels, the unit has achieved ISO 9001, ISO

14001 & OHSAS 18001 certifications within a year. All the managers in the unit were

trained in EHS Risk Management, with the help of National Safety Council, to identify

hazards and implement risk reduction plans.

Water: At the time of acquisition, the Kovai unit used

30 KL of water per tonne of board. The Tamil Nadu Pollution Control Board requires all

effluents from the mill to be discharged on Company-owned land at a maximum of 35 KL/acre.

This limited the total production capacity of the unit. Petax filters were installed, at

substantial investments, to clean and recycle the processed water, thereby drastically

reducing the water usage to a mere 11 KL per tonne of board. Studies were conducted to

establish the significant potential for rainwater harvesting and the unit is gearing up to

create a potential of 2,57,257 KL per annum of rainwater harvesting before the 2006

monsoon. Rainwater thus collected should help meet nearly 25% of the total water

requirement. Further efforts to reduce consumption and improve recycling of water are

underway.

Energy: Various energy saving activities have been

explored and implemented due to which 7 MwH power is already being saved every day.

Safety: During the last 7 months of 2004-05, the unit

did not have a single lost time accident. |

|

|

ITC believes that waste is a useful resource that

can be recycled either within the Company or can be used as raw material elsewhere. During

2004-05, ITC units generated 2,80,891 tonnes of solid waste (34.9% higher than the

previous year). This included the waste generated by the newly acquired Kovai paperboards

unit and the merged hotel properties. All the businesses continued efforts to reduce waste

and achieve 100% recycling. This year, 80.5% of the total waste generated was recycled

(53.3% in 2003-04).

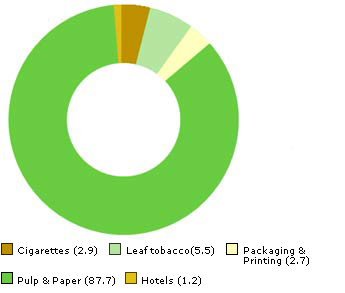

Breakdown of Solid Waste Generation (In Percentage)

Significant progress was made by a large number of units towards achieving zero solid

waste, through reduction or elimination of waste at source, coupled with recycling and

reuse practices.

The Cigarette factory at Kolkata, the Leaf processing factory at Chirala, the Packaging

& Printing unit at Tiruvottiyur, the Cast coating unit at Bollarum and the ITC Grand

Central Hotel at Mumbai achieved zero solid waste status through 100% recycling. In these

units, the waste generated was either reused internally or 100% recycled.

The Cigarettes, Leaf Tobacco and Packaging & Printing businesses achieved over 90%

recycling of solid wastes generated. |