-

Category: Environment

The issue of waste management has assumed critical significance for the country today. Over the last few decades, the amount of waste generated has gone up considerably as a direct consequence of increasing population, rapid and unplanned urbanisation, higher consumption levels and inadequate infrastructure. However as a country, appropriate waste management mechanisms have not received adequate focus. As a result, most of the waste being generated today finds its way to landfills, causing a severe strain on the ecology. Heaps of unattended waste, foraged by cattle and rag-pickers alike, have become a common sight both in urban and rural areas of the country.

Apart from the increasing pressures on natural resources, the issue of burgeoning waste also contributes to soil and ground water contamination and Greenhouse Gas (GHG) emissions, which are threatening the quality of life throughout India.

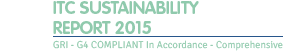

As a responsible Corporate Citizen, ITC's approach on this important aspect is depicted below.

In 2014-15, ITC Units generated 7,91,227 tonnes of waste (7,11,887 tonnes in 2013-14). This 11.1% rise in total waste generated over last year was primarily due to non-availability of low ash content coal and augmentation of virgin pulp production in Bhadrachalam Unit of the Paperboards and Specialty Papers Division. This Unit, which accounted for 79.8% of the total waste generated in ITC during 2014-15, reported an increase of 16.3% in waste generation as compared to previous year.

In addition, there has been an expansion in the reporting boundary. The following business units/ activities have been included in the Sustainability Report for 2014-15:

Snacks and Noodles Unit of Foods Business at Malur (Karnataka), ITC Grand Bharat at Gurgaon and My Fortune at Bengaluru of the Hotels Business, clonal plantation development activities of Paperboards and Specialty Papers Business at Bhadrachalam, together with Classic Golf Resort in Gurgaon, ITC Kakatiya in Hyderabad and Fortune Resort Bay Island in Andaman and Nicobar Islands, being units of subsidiary companies.

| Tonnes | % | |

|---|---|---|

| Paperboards and Specialty Papers | 721,211 | 91.15 |

| Leaf Tobacco | 22,198 | 2.81 |

| Packaging and Printing | 19,455 | 2.46 |

| Foods | 12,035 | 1.52 |

| Cigarettes | 9,417 | 1.19 |

| Hotels | 5,315 | 0.67 |

| Personal Care Products | 1,335 | 0.17 |

| Others (Offices, ITC Infotech, Lifestyle Retailing) | 263 | 0.03 |

| Total | 791,227 |

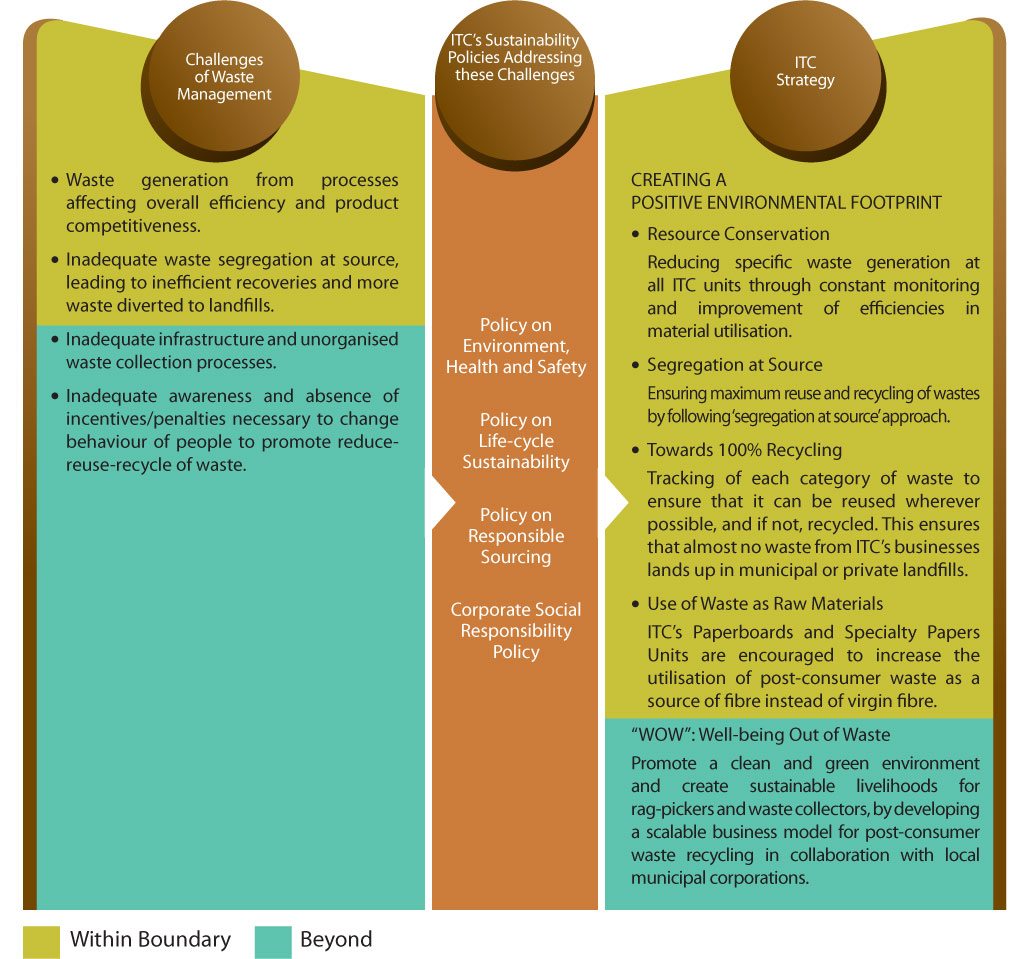

In order to continually improve performance on resource conservation, all ITC Units have developed systems to track and monitor the specific waste generation (waste generated per unit of product/ service). Considering the significant share of Paperboards and Specialty Papers Business in the total waste generated by ITC (as demonstrated in the above table), specific focus has been laid on monitoring the performance of the Units under this Business. Specific waste generation of these Units are as follows:

| Unit |

|

Percentage Deviation |

Increase/ Decrease |

Primary factors | |||||

|---|---|---|---|---|---|---|---|---|---|

| Bhadrachalam | 1044.3 | 1171.1 | 12.1% | Increase | Non availability of low ash content coal, and rise in virgin pulp production (avoiding use of imported pulp). | ||||

| Bollaram | 75.7 | 71.0 | 6.2% | Decrease | Process improvement and waste reduction programmes | ||||

| Kovai | 209.5 | 210.2 | 0.3% | Increase | Increased use of lignite and deoiled bran (higher ash content as compared to coal) | ||||

| Tribeni | 2517.0 | 2055.6 | 18.3% | Decrease | Replacement of old boilers with a new efficient boiler | ||||

Average generation of 1200kg of solid waste per tonne of product for similar integrated pulp and paper mills**

**Reference: Centre for Science and Environment Report, 'All About Paper' (2004)

Historically, due to limited options for recycling of lime sludge (a waste generated from chemical recovery process in Bhadrachalam Unit), some amount was being utilised by cement plants, with the bulk stored in lagoons within the premises, incorporating adequate precautions to prevent adverse impacts on soil and ground water. In 2014-15, the Unit tied up with more cement plants and around 14,000 tonnes of waste was recycled through this arrangement. The accumulated quantity of lime sludge in these lagoons is estimated to be around 2.5 lac tonnes and it is expected that the entire amount of accumulated lime sludge will be utilised within the next 3 years.

Of the total waste generated by ITC in 2014-15, only 3.2% by weight can be categorised as hazardous waste as per Indian statues. 94.5% of this hazardous waste was recycled by authorised external agencies, and the balance 5.5% was disposed of or stored completely in accordance with applicable statutes. All ITC Units have established systems and procedures to verify the relevant authorisations and licenses of external agencies for transporting, recycling or disposing the hazardous wastes, in compliance with applicable regulations and norms. Further, Corporate EHS periodically verifies the compliance in each of the ITC Units. During 2014-15, apart from hazardous wastes transported to external treatment sites by authorised transport agencies as applicable, no other hazardous wastes were transported between locations owned or managed by the organisation.

The table below depicts the final destinations of the total hazardous wastes generated during 2014-15:

| Total hazardous waste generated | 25,111 |

| Hazardous waste carried over from previous year and disposed in 2014-15 | 40 |

| Recycled | 23,771 |

| Incineration + Landfill | 1,314 |

| On-site storage | 66 |

(All values in Tonnes)

During 2014-15, out of the total non-hazardous waste generated in ITC Units, 99.97% waste was reused/ recycled. The details of the destination for the major waste categories, which contributed to more than 85% of the total non-hazardous waste generated in ITC units in 2014-15, are given below:

| Non-hazardous waste category | Generated by | Quantity of generation (Tonnes) | Waste destination |

|---|---|---|---|

| Fly ash generated from coal-fired boilers | Units of Paperboards & Specialty Papers and Leaf Tobacco Businesses | 3,98,369 | Used by cement and brick manufacturers |

| Lime sludge | Bhadrachalam and Tribeni Units of Paperboards & Specialty Papers Business | 2,07,466 | Utilised in-house as well as by external cement manufactures |

| Bottom ash from coal-fired boilers | Units of Paperboards & Specialty Papers and Leaf Tobacco Businesses | 51,091 | Used for brick manufacturing and filling of low-lying areas |

| Wood waste from chipping operation | Bhadrachalam Unit of Paperboards & Specialty Papers Business | 24,517 | Used as a fuel in an in-house boiler |

ITC strives to maximise resource efficiency in all its Units so as to reduce waste generation to the extent possible. Since generation of waste cannot be completely eliminated due to limitations in processes and technology, all ITC Businesses/ Units endeavour to work towards 100% recycling of generated waste. Approach of 'segregation at source' along with focused attention on identifying and tracking of all waste streams till its final disposal have helped to enhance the performance in waste recycling across all Units. During 2014-15, 99.8% of the total waste generated within the units was recycled.

Units that recycled more than 99% of generated waste

Use of post-consumer waste as raw materials by the Paperboards and Specialty Paper Units at Kovai and Bhadrachalam has enabled the Company to further expand its waste recycling footprint. Efforts at ITC Units to recycle the entire waste generated along with utilisation of externally generated waste paper as a source of fibre in the above mentioned Paperboards and Specialty Paper Units, have helped the company to maintain its solid waste recycling positive status for the 8th consecutive year (refer the table below)

| 2007-08 | 2008-09 | 2009-10 | 2010-11 | 2011-12 | 2012-13 | 2013-14 | 2014-15 | |

|---|---|---|---|---|---|---|---|---|

| Total Waste generated (tonnes) | 3,52,970 | 4,90,180 | 5,78,865 | 6,38,405 | 6,63,796 | 6,82,405 | 7,11,887 | 7,91,227# |

| Waste recycled (tonnes)® | 3,49,264 | 4,84,287 | 5,77,766 | 6,37,452 | 6,62,978 | 6,81,129 | 7,11,033 | 7,89,720 |

| % Recycled | 98.90 | 98.80 | 99.80 | 99.80 | 99.90 | 99.8 | 99.9 | 99.8 |

| Un-recycled waste (tonnes) | 3,706 | 5,893 | 1,099 | 953 | 818 | 1276 | 854 | 1592 |

| External wastes used as raw materials (tonnes) | 1,63,245 | 1,25,337 | 1,25,931 | 1,19,002 | 1,15,414 | 1,18,462 | 1,09,998 | 1,14,563 |

| Waste recycling footprint (%) * | 145 | 124 | 122 | 119 | 117 | 117 | 115 | 114 |

| # 85 Tonnes of waste, carried over from previous year was disposed in 2014-15 but not included in 'total waste generated' * Waste Recycling footprint (%) = (Waste recycled + external waste used as raw material)*100/Total waste generated in ITC ® Waste recycled include 8891 tonnes of waste composted |

||||||||

"Wealth Out of Waste (WOW)", a recycling programme initiated in April 2007 by the Paperboards & Specialty Papers business of ITC, has evolved into a corporate level program with scope enhanced to "Well-being out of waste" focused on creating scalable solutions for spreading awareness about recycling, encouraging people to segregate & dispose waste responsibly and creating sustainable livelihoods for people working as rag pickers.

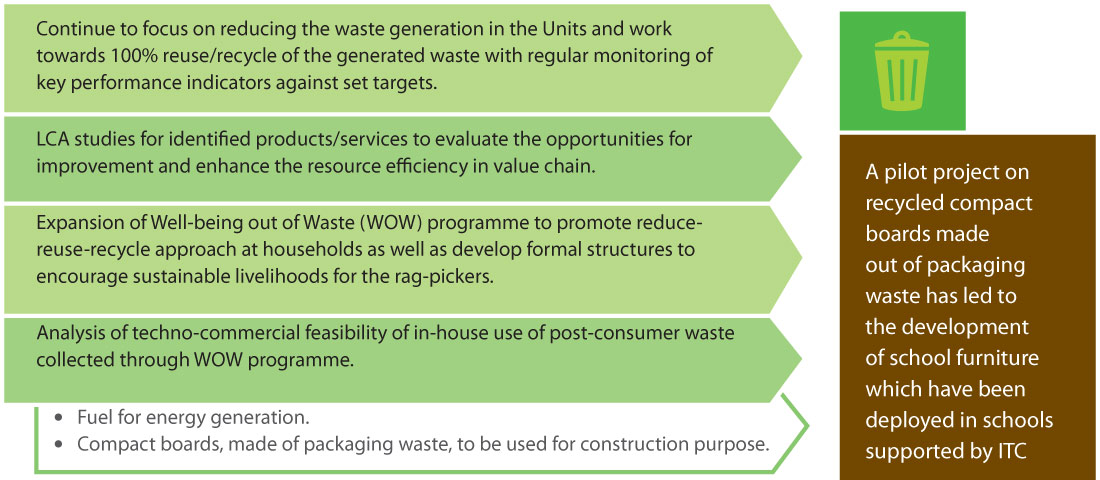

As part of ITC's ongoing efforts towards maximising value capture from post-consumer waste, a pilot project on recycled compact boards made out of packaging waste has led to the development of school furniture which have been deployed in schools supported by ITC. Applications for these boards within ITC facilities are also being explored. In addition, studies are being carried out to explore viability of converting waste plastic to fuel.

In 2013-14, ITC started accounting for the waste generated from the operations of exclusive third party manufacturing (TPM) Units catering to the notebook segment of ITC's Education and Stationery Product Business as well as ATC Limited, ITC's associate company. To expand this coverage, this year TPM Units for Cigarette Business have also been included in the reporting boundary. Performance of these Units is detailed below. ITC will continue to progressively extend this coverage. Quality of data continues to be a challenge in the TPM facilities. Capacity building and regular review of performance data will be continued so as to improve the data quality in the coming years.

| Supply Chain Members | Total Waste Generated (in tonnes) | % Recycled |

|---|---|---|

| Exclusive TPM Units for Notebook segment | 3879 | 95.3 |

| Exclusive TPM Units for Cigarette Business | 1201 | 99.3 |

| ATC Limited | 752 | 99.9 |